Upcoming & Past Events

|| SPE ATCE 2025 || Transformer vs Classical Machine Learning: Harnessing Normalization for Enhanced Asset Life Prediction

Transformer vs Classical Machine Learning: Harnessing Normalization for Enhanced Asset Life Prediction

K. Chaudhari, Prescient Devices Inc.; R. Whitney, Precision Drilling; P. Acosta, Prescient Devices Inc; A. Wang, Prescient Devices Inc.

Abstract

The advent of artificial intelligence (AI) and machine learning (ML) solutions enable detailed time-series data analysis previously thought impractical to impossible. This paper highlights the development and deployment of a Transformer-based Asset Life Model (ALM) which outperforms previously deployed classical machine-learning approaches for predicting drilling equipment component lifetimes. The use of advanced normalization methods enables consistent performance comparisons across a wide array of assets which may be deployed on different rig types and configurations, geologic basins, and varying operational conditions while offering a flexible framework to accommodate future expansion in data volume and diversity. Furthermore, factors such as manufacturer attributes, like make and model, can be efficiently incorporated and compared. Said features form the cornerstone of insights which influence supply chain and operations optimization efforts which resulted in a 40% reduction in operating costs. This paper presents a novel Context-Conditioned Normalization (CCN) layer, the supporting technical stack - from data governance through hyper-parameter optimization, ML Operations (MLOps), and field rollout - offering a blueprint for industrial-scale deep learning.

The contents of this paper will be presented at SPE ATCE Conference on October 21, 2025 in the AI-Driven Drilling: Providing Insights and Unlocking Performance.

Meet with Prescient at the SPE ATCE Conference

Related Materials

Driving Operational Excellence: The Impact of Digital Twin Technology on Super Single Rigs,” Precision Drilling

Learn how Precision Drilling enhances equipment monitoring and diagnostics for their Super Single fleet while bringing visibility into mud pump health and balancing operational pressure on components with Prescient’s digital twin solution.

Precision Drilling Leads the Industry in Equipment Quality Using Asset Digital Twins

Read about the digitization process of Precision Drilling’s drilling equipment with the introduction of an AI-based Asset Life Model that predicts component life, optimizes component performance, and compares component quality across different operating conditions and geographical regions.

Operational Excellence: Transforming Oil and Gas Asset Health Using Operational Digital Twins

Download Prescient’s whitepaper on how our solution tailors to the specific needs of the oil and gas industry for onshore and offshore drilling.

|| Darcy Partners || Drilling Surface Equipment Reliability via IoT & Predictive Tools with Precision Drilling

Unplanned equipment failures continue to pose a major challenge in drilling operations, leading to downtime, safety risks, and rising costs. This session will explore how IoT-enabled devices, enhanced data integration, and real-time predictive analytics are revolutionizing drilling teams' ability to proactively monitor and prevent failures in surface equipment such as top drives, mud pumps, and power systems. By connecting siloed data sources and leveraging advanced analytics, operators can detect early warning signs of mechanical stress, optimize maintenance planning, and improve equipment lifespan. The discussion will also highlight practical strategies for integrating modern analytics tools with legacy systems, empowering teams to shift from reactive troubleshooting to predictive failure prevention and operational excellence. (Excerpt from Darcy Partners event link)

Download the webinar deck presented by Precision Drilling

|| MIT MTL || Startup Showcase for Microsystems Technology Laboratories’ 40th Anniversary

We are excited to participate in the MIT MTL Startup Showcase as part of the Microsystems Technology Laboratories' 40th anniversary celebration. Our founders, Dr. Andy Wang, Dr. Pablo Acosta, and Prof. Charles Sodini, all came from MTL, which built a solid foundation for our work in data system optimization. Join us at the showcase to see our distributed, graphical workflow technology to enable rapid implementation, iteration, and innovation of industrial and energy data solutions. The MTL40 celebration is jointly hosted with the MIT Research and Development Conference.

Link to 2024 MIT Research and Development Conference | Link to MTL40 Website

|| IADC Annual General Meeting (AGM) || Real-time Data Wrangling through Distributed Data Engine Technology

Real-time Data Wrangling through Distributed Data Engine Technology: Russell Whitney, IIoT Manager, Precision Drilling, Andy Wang, CEO, Pablo Acosta-Serafini, Prescient Devices, Inc.

Our presentation introduces a distributed low-code data engine capable of working with massive real-time data from warehouses like Snowflake. This drag-and-drop, hierarchical, and graphical data workflow builder efficiently processes data for upstream analytics. It enables quick engineering of complex real-time data streams, supporting tasks like anomaly detection. The engine’s scalability allows easy deployment and customization, facilitating rapid scaling across rig fleets. We will then showcase how this data engine serves as the cornerstone for implementing a digital twin solution for rig operations, highlighting the transformative impact of rapid data wrangling on rig operations.

|| University of Houston || Research Seminar Series: Scaling Data and AI for Upstream

Scaling Data and AI for Upstream: Andy Wang, Ph.D., CEO, Prescient Devices Inc.

Data science is experiencing strong growth in oil & gas, but scaling data science solutions to production is still a major challenge. This talk will explore the top challenges in scaling production-grade data science solutions from generating high-quality data at massive scale to solving computing resource limitations and database bottlenecks. We will use a drilling digital twin solution as a use case to show how to scale this solution to support 100+ rigs and process 2.1-Billion real-time data points and 57-Million database queries per day

|| Maintenance and Reliability Symposium (MaRS) || Building Effective Visualization for Reliability Monitoring

Building effective visualization for reliability monitoring: Nathan Reese, Manager Alpha Remote Operations, Precision Drilling, Andy Wang Ph.D., CEO, Prescient Devices Inc.

We will introduce advanced visualization techniques designed specifically for reliability monitoring in the manufacturing and energy sectors. We will demonstrate the effective use of visualization tools to anticipate potential failures and fine-tune maintenance schedules, ensuring superior operational reliability and efficiency.

|| SPE ATCE 2024 || Deploy Distributed Real-time Data Pipelines Across Cloud and Edge to Process Rig Data for Easy Data Fusion and Processing

Deploy distributed real-time data pipelines across cloud and edge to process rig data for easy data fusion and processing: Russell Whitney, IIoT Manager, Precision Drilling, Andy Wang, CEO, Pablo Acosta-Serafini, Prescient Devices, Inc.

We will showcase these technologies’ roles in enhancing predictive capabilities, optimizing resource allocation, and improving geological assessment accuracy. We will delve into advanced data analysis techniques that reduce uncertainties and enhance the efficiency of exploration and production processes.

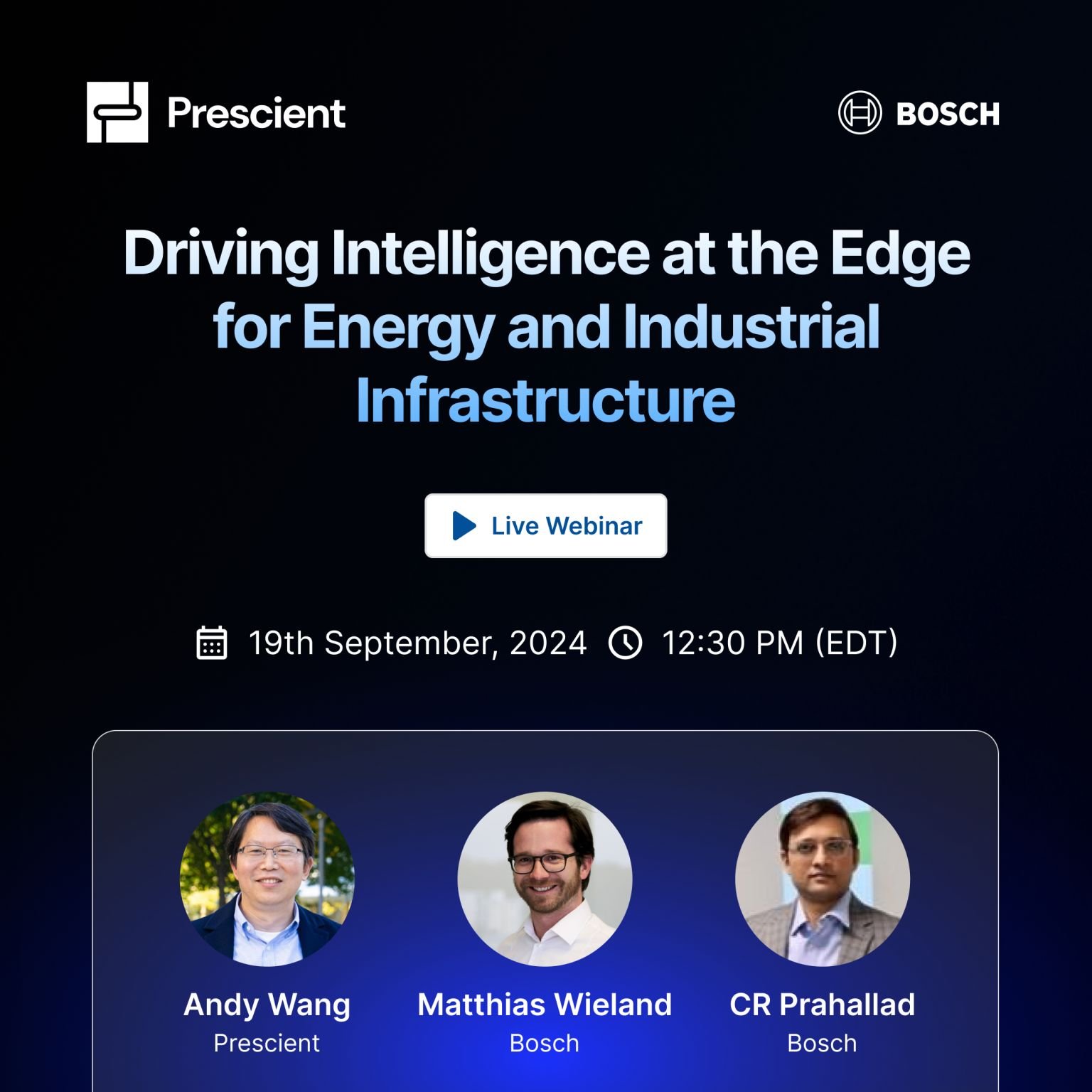

|| Intel Partner Alliance Webinar Series || Driving Intelligence at the Edge for Energy and Industrial Infrastructure with Bosch

Driving Intelligence at the Edge for Energy and Industrial Infrastructure: Matthias Wieland, Global Partnermanagement and Sales Head Europe, Bosch, CR Prahallad, Head of Customer Solutions, Bosch, Andy Wang, CEO, Prescient Devices Inc.

The Bosch* Digital Twin – Integrated Asset Performance Management (IAPM) improves plant machinery and processes by addressing predictable business challenges. It offers engineering insights to enhance Overall Equipment Effectiveness (OEE), reduce unplanned downtime and maintenance costs, and improve quality. Business insights from IAPM help understand asset criticality, improve plant efficiency, and lower failure mitigation costs through predictive maintenance. This approach supports Reliability Centered Maintenance and Total Productive Maintenance. Its modular design and collaborative, customer-involved solution building provide a unique, immersive experience.

|| IADC Advanced Rig Technology (ART) || Real-time Data Wrangling through Distributed Data Engine Technology

Real-time Data Wrangling through Distributed Data Engine Technology: Russell Whitney, IIoT Manager, Precision Drilling, Andy Wang, CEO, Pablo Acosta-Serafini, Prescient Devices, Inc.

Our presentation will introduce a distributed low-code data engine that efficiently processes real-time data for upstream analytics. This allows quick engineering of complex real-time data streams and supporting tasks like anomaly detection.

|| EAGE Local Chapter: Houston || Technical Talk: The Impact of High-speed, Real-time Data Pipelines on AI and Data Science in Oil and Gas Value Chain

Technical Talk: The Impact of High-speed, Real-time Data Pipelines on AI and Data Science in Oil and Gas Value Chain, Andy Wang Ph.D., CEO, Prescient

Many AI applications in the oil and gas industry require real-time data. However, this real-time data can come from variety of data sources: sensors, PLCs, SCADA systems, historians, and more. These data sources also have very different protocols, locations, data rates, and etc. This talk will speak on data pipeline technologies that can conquer these data disparity challenges at scale. Use cases in upstream from drilling to characterization to production will be discussed.